|

Sydney 02 8004 2111 Adelaide 08 7221 2555 |

Melbourne 03 9038 8555 Perth 08 64616255 Email: sales@unicorn.net.au |

Brisbane 07 3139 1555

|

|

|

||

Binding Info

- Is there a single machine that does all styles of binding?

- Why can't I punch 50 or 100 pages at a time?

- Are there any fully-automatic binding machines?

- Which binding machine is considered the most reliable?

- What types of covers can I use with my documents?

- Is there a difference between plastic comb, spiral coil and wire binding?

- About Plastic Comb

- About Spiral Coil

- About Double Loop Wire

- Can I use double loop wire on a plastic comb machine?

- Are there combo machines that do both comb and wire binding?

- Wire Binding Pitch Explained

- A Word about Quality of Manufacture

- What are Dies?

_____________________________________________________________________

Is there a single machine that does all styles of binding?

Yes! There are machines such as the Diamond Punch which allows the operator to choose between binding formats. These machines are primarily used for high volumes applications punching 35 sheets per punch. Multi-die machines are generally used in print and copy shops or corporations which do their own in-house document production. They are “punch only” machines therefore require separate wire closers, coil inserters and/or comb closers to finish the document relative to the preferred binding style. Each punching die (binding style hole pattern) can be purchased separately and swapped over as required.

_______________________________________________________________________

Why can't I punch 50 or 100 pages at a time?

The simple answer is the physics of paper. Paper tends to compress then warp at a particular thickness. In turn the stacks of paper also warp and will not produce clean perforations.

Of course there are machine which use laser or other methods of perforating but they are of a high commercial grade and cost over $50,000!

Desk top binders vary in their punch capacity relative to the quality of the equipment and the leverage and strength of the handle and punching dies (if manual punch) or strength of the motor and punching dies (if electric punch)

_______________________________________________________________________

Are there any fully-automatic binding machines?

All binding machines require some level of human interaction. Higher-end binding machines electrically punch generally using a foot pedal. This significantly speeds up the binding process and eliminates operator fatigue. The perforated wads need to be inserted over the binding element manually.

_______________________________________________________________________

Which binding machine is considered the most reliable?

High tensile hardened steel punching dies (the cutters) are essential for producing professional documents. Poorly manufactured machines have cheap soft metal dies which are unreliable and produce frayed holes. The machine should be of all-metal constructed which will stand the test of time over a plastic, clip-lock constructed machine which makes servicing inside the machine inaccessible. If the machine looks plastic in appearance and is poorly finished, chances are the general manufacture, such as the main frame, punching dies and internal components are also inferior.

_______________________________________________________________________

What types of covers can I use with my documents?

Well manufactured binding machines will easily punch though all types of card stock, PVC and polypropylene binding covers. Be sure to only punch 2 sheets of PVC per punch and one sheet of polypropylene as plastics are very abrasive compounds. NEVER use overhead transparencies as they will cause damage to your machine.

_______________________________________________________________________

Is there a difference between plastic comb, spiral coil and wire binding?

Yes! They are all completely different styles of binding specific to the type of finish you wish to achieve and the intended purpose of your documents.

_______________________________________________________________________

|

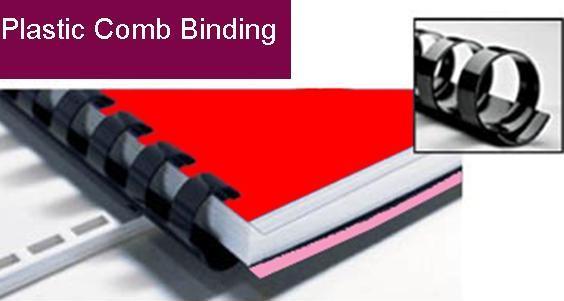

Plastic Comb: This style is most often used to bind internal documents or where presentation is not as important. Due to the spineThe main advantage with plastic comb binding is that it allows the binding of documents as thick as 400 sheets whilst spiral and wire binding is more limited to document thickness and documents can be re-opened after binding to insert additional pages as required. Each binding style use entirely different binding elements. Combs fit into 21 rectangular holes. |

_______________________________________________________________________

|

Spiral Coil: is very robust (will not squash), lies flat and turns 360 degrees for ease of reading making coil binding perfect for training manuals, tenders and educational resources. Each binding style use entirely different binding elements.Spiral coils are a continuous sprial which winds through a series of closely spaced round holes. |

_______________________________________________________________________

|

Double Loop Wire binding has a professional finish and allows the document to lie flat and be turned 360 degrees. Wire binding is often the preferred method for reports and documents which need to impress. Double loop wire loops fit into 34 or 23 (see info on wire pitch) square holes which accommodates the shape of the double loops. |

______________________________________________________

Can I use double loop wire on a plastic comb machine?

No. The spacing and shape of the holes are not cross-compatible. Industry standard binding wire is manufactured to fit into either 34 or 23 square holes punched down an A4 page. Plastic comb binders perforate 21 rectangular holes punched down an A4 page. This shape snuggly fits the plastic binding element. The exception is Ibiwire. This is a 21 loop binding wire purposely manufactured to fit into plastic comb holes. These wires are not industry standard and the finished product is significantly compromised.

_______________________________________________________________________

Are there combo machines that do both comb and wire binding?

Yes! But they vary in quality of manufacture. For instance electric desktop machines tend to compromise on quality. High-end manual machines such as the MacCombo has quality componentry which is specifically designed to bind in both wire and comb and produce first class documents.

Combo machine have both a wire punching die along with a plastic comb punching die onboard. The machines also have a wire closer and a comb closer integrated into the design of the machine.

Combo machines should give the option to either bind in 2:1 or 3:1 in the double loop wire

_______________________________________________________________________

|

This shows 2 thin documents. The top document is bound in small sized 2:1 pitch wire and the other bound in 3:1 pitch wire. |

Wire Binding Pitch ExplainedOne of the greatest considerations when choosing a wire binding machine is the fact that you are required to choose from either 3:1 pitch (3 holes per inch) or 2:1 pitch (2 holes per inch). If you select a 3:1 double loop binding machine you are limited to binding books that are 12mm or smaller. In the past, if you selected a 2:1 wire binding machine you would be limited to books that were from 15mm thick up to 28mm thick. However with the introduction of new smaller diameter 2:1 pitch wire, a 2:1 wire binding machine can now be used to bind books as thin as 6mm.

|

_______________________________________________________________________

_______________________________________________________________________

Punching Dies

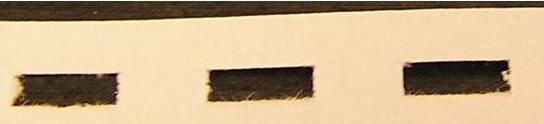

Punching dies cut the holes in the paper. It is very important that you choose a machine with hardened steel dies which will produce a clean, crisp perforations. Concaved or diamond cut dies are manufactured from hardened steel and bare the load of the punch over sharp steel edges which cuts through the paper wads cleanly.

Cheap chisel dies which are generally soft metal uses force without cutting. This method of punch produce frayed holes which makes binding difficult and gives an unprofessional finish to your document.